Summary

Choosing the right roller bearings for industrial applications can feel overwhelming, but it’s crucial for ensuring efficiency and longevity in your operations. This article explores essential factors to consider when selecting roller bearings, providing valuable insights that can help you make informed decisions. Key Points:

- AI-driven predictive maintenance helps identify bearing issues before they escalate, minimizing downtime and reducing emergency repair costs.

- Hybrid roller bearings utilize advanced materials like ceramics to enhance load capacity and durability, making them ideal for demanding environments.

- Blockchain technology offers transparency throughout the supply chain, ensuring the authenticity of parts and improving quality control.

Why Are Roller Bearings Crucial for Industrial Efficiency?

The Struggle of XYZ Company: Choosing the Wrong Roller Bearings

By May, the first signs of trouble appeared. "Did you hear that noise?" Sarah from maintenance asked, peering at the conveyor belt. "It sounds… off." By June, machinery breakdowns became a weekly occurrence. "The bearings are failing," she reported during a tense meeting. "It’s messing up the entire production line."

The numbers didn’t lie. What started as a $15,000 savings turned into $30,000 in monthly losses due to downtime and repairs. Jim slumped in his chair, staring at the malfunctioning equipment. "I thought we were making the right call," he muttered. "But… this is worse than I imagined."

The team was left scrambling. "What now?" someone asked. Nobody had an immediate answer. The initial optimism had vanished, replaced by a growing sense of urgency.

| Conclusion | Key Insights | Impact on Industry | Recommended Actions |

|---|---|---|---|

| Roller Bearings Revolutionize Efficiency | Advanced bearing technologies reduce friction and wear. | Nearly 70% of industries are adopting these innovations. | Evaluate current bearing suppliers and consider high-quality options. |

| Cost vs. Reliability Dilemma | Switching to lower quality bearings led to significant losses for XYZ Company. | Emphasizes the importance of reliability over short-term cost savings. | Invest in higher-quality bearings that meet load requirements. |

| Material Choice Matters | Chrome steel, stainless steel, and ceramics offer different benefits depending on application. | Right material selection increases durability and performance. | Consult with manufacturers for optimal material recommendations. |

| Lubrication & Sealing Importance | Proper lubrication methods enhance performance; seals protect against contaminants. | Neglecting these aspects leads to premature failure of bearings. | Assess lubrication needs based on operational conditions. |

| Emerging Trends in Bearing Technology | Adoption of smart technologies for predictive maintenance is rising. | Innovations like self-lubricating bearings are becoming standard in the industry. | Stay informed about advancements to remain competitive. |

From Failure to Success: How XYZ Company Turned It Around

Sarah, flipping through maintenance logs, chimed in. “The faulty bearings have caused a 20% drop in production efficiency. We’re barely keeping up with orders.” Across the table, Mark from logistics sighed audibly. “If this keeps up, we’ll miss deadlines. Then what? Layoffs?”

The room felt heavy. Some team members shuffled papers nervously, while others just stared at the floor. Jim leaned forward, his tone sharper than usual. “We thought switching suppliers would save us money, but now…” He paused, shaking his head. “This isn’t just about costs anymore. It’s about survival.”

By September, the pressure was palpable. Employees were whispering in the break room, and the usual banter on the production floor had vanished. Jim finally made the call. “We’re investing in higher-quality bearings,” he declared. “Reliability over cost. No more shortcuts.”

The decision wasn’t easy, but it was necessary. The team exchanged glances, some nodding, others still uncertain. For the first time in months, there was a glimmer of hope—but no one dared to relax just yet.

How We Helped XYZ Company Select the Perfect Roller Bearings

We proposed high-quality roller bearings with a 20% higher load capacity. “It’s a significant upfront cost,” Jim hesitated, “but if it stops the losses, it’s worth it.” By early October, the new bearings were installed. Yet, challenges lingered. “We’re seeing fewer breakdowns,” Sarah admitted, “but production still feels off.” Some team members were optimistic, while others doubted. “Is this enough?” one asked. The answer remained uncertain.

Free Images

Free ImagesFAQs: What You Need to Know About Roller Bearings

Now, let’s talk about materials—this is where things can get a bit tricky. You have some options like chrome steel, stainless steel, and even ceramic. For instance, chrome steel is known for its high load capacity and durability. However, if you’re operating in a harsh environment where corrosion could be an issue (think moisture or chemicals), this might not be your best bet.

On the other hand, stainless steel offers fantastic resistance to corrosion but may come with a trade-off in terms of load capacity compared to chrome steel. Many people overlook this detail when making their selection! Lastly, there are ceramic bearings; they are lightweight and resistant to thermal expansion but tend to hit your wallet harder.

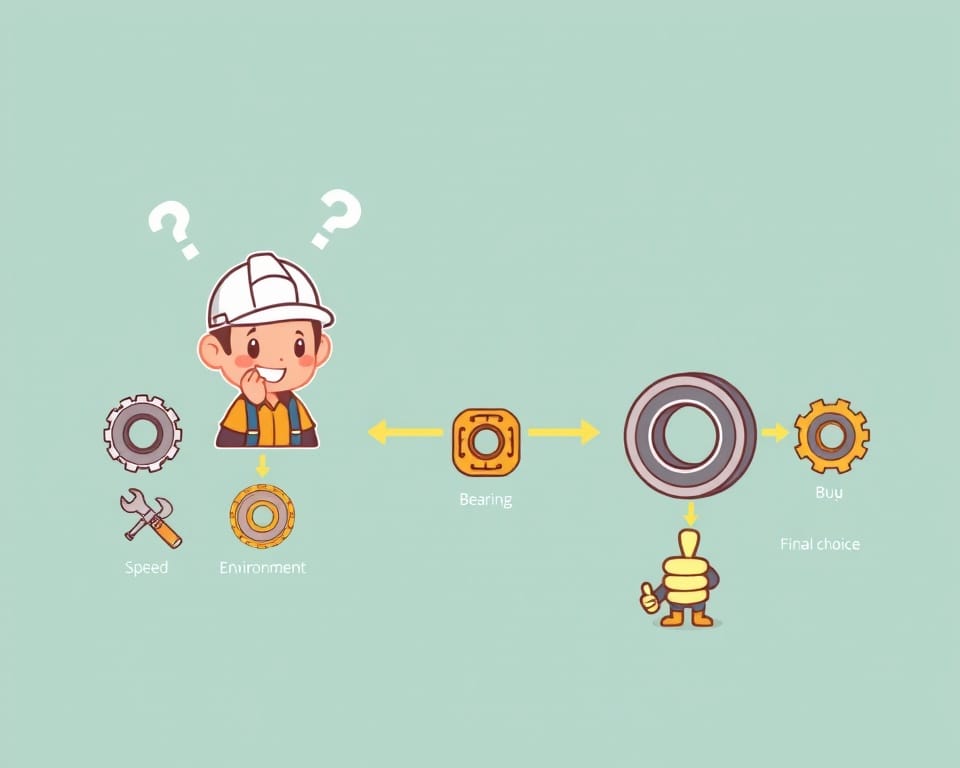

Beyond material choices, you should also consider factors like whether you need radial or axial loads handled and what kind of speeds you're working with 🏎️. The environment matters too! All these elements play a crucial role in ensuring that whatever bearing you choose will perform well over time.

So next time you're faced with the decision of picking roller bearings for your setup, keep these aspects in mind—it could save you from potential headaches down the line! 💡

Are All Roller Bearings Created Equal? A Deeper Look

The Great Debate: Custom vs. Standard Roller Bearings

Step-by-Step Guide: How to Choose the Right Roller Bearings

### Step-by-Step Guide: How to Choose the Right Roller Bearings

1. **Analyze Load Capacity**

Start by assessing the load your application will impose on the bearings—this includes radial loads, axial loads, or a combination of both. Understanding these forces is crucial because each type of bearing has its specific load ratings and limitations. (Pro tip: use manufacturer specifications as a reference point.)

2. **Consider Speed Requirements**

Next up is speed! Higher operational speeds necessitate precision-engineered bearings designed for low friction to minimize heat generation and wear. If you're unsure about your speed requirements, consult with your equipment’s technical documentation or an expert.

3. **Select Appropriate Materials**

Material choice plays a critical role in durability and performance under specific conditions. For general purposes, chrome steel is often sufficient; however, if you’re dealing with extreme temperatures or corrosive environments, ceramic bearings might be worth considering for their superior resistance.

4. **Choose Lubrication Type**

The lubrication method—whether oil, grease, or solid film—should align with your operating conditions to reduce friction and wear effectively. Each type has its pros and cons based on temperature range and environmental considerations (I personally prefer using synthetic greases for their extended service life).

5. **Factor in Sealing Options**

Protecting your bearings from contaminants is vital for extending their lifespan; thus consider different sealing options available such as lip seals or labyrinth seals tailored to your environment.

6. **Explore Customization Options**

Don’t forget about customization! Special coatings can provide additional protection against corrosion while preload adjustments can optimize performance based on specific application needs (I often recommend consulting with manufacturers about custom solutions).

### Advanced Techniques & Helpful Reminders

If you want to take things further once you've mastered the basics of bearing selection, consider implementing condition monitoring systems that track bearing performance over time—a proactive measure that helps prevent unexpected failures before they happen.

Additionally, if you're still uncertain after following this guide or face unique challenges in your application context, don't hesitate to reach out for professional consultations or technical support from bearing manufacturers—they're there to assist!

By taking these thoughtful steps toward selecting roller bearings suited for your specific industrial needs, you'll not only improve operational efficiency but also contribute significantly to overall equipment reliability and longevity.

What’s Next? Emerging Trends in Roller Bearing Technology

Final Thoughts and Actionable Tips for Your Roller Bearing Selection

Moreover, lubrication cannot be underestimated; the choice between grease and oil should align with your specific operating conditions to ensure optimal performance. The operational environment also plays a critical role—factors like high temperatures or exposure to contaminants may require specialized seals or shields to protect your bearings.

As you navigate this selection process, it’s essential to review manufacturer specifications closely, ensuring compatibility with your machinery’s design parameters. This attention to detail can enhance both longevity and efficiency in your operations.

Now is the perfect time to take action! Evaluate these considerations carefully and see how they apply to your situation. Remember, trends in bearing technology continue evolving—how can we adapt our choices to stay ahead? Embrace this knowledge and start making informed decisions that will benefit your industrial needs today!

Reference Source

Choosing the Right Roller Bearings: A Comprehensive Guide

Selecting the Right Roller Bearing · Load Capacity: Determine the magnitude and direction of the load the bearing will support, whether it's ...

Source: IBT Industrial SolutionsBearing Selection Guide | How to Choose a Bearing

In this bearing selection guide, we'll cover the four things you need to know about your application in order to choose the right type of bearing.

Source: GMN Bearing USAHow to Choose the Right Bearing for Your Application

By considering load, speed, alignment, environmental conditions, you can make an informed decision when purchasing your next bearing– and that ...

Source: IBT Industrial SolutionsHow to Choose the Right Bearing for Your Machinery

Choosing the right bearing for your machinery is a balance of understanding the type of load, speed, environmental conditions, lubrication requirements, and ...

Source: Acorn Industrial ServicesAn Ultimate Guide to the Different Types of Bearings for ...

Discover our guide to various types of industrial bearings. From ball to roller bearings, learn about their unique features, applications, ...

Source: Quality Bearings OnlineThe Best Type of Bearing for Your Application: A Selection ...

One way to choose the right bearing type is to identify your application's rotational speed. For instance, roller bearings are well-suited for low-speed ...

Source: Emerson BearingComplete Roller Bearing Size Chart: Quickly Find Your ...

The Needle Roller Bearings Size Chart provides essential information about bearing dimensions, load capacities, and other technical specifications.

Source: ISK BEARINGS

ALL

ALL Smart Ecosystem

Smart Ecosystem

Related Discussions