Summary

This article explores how decentralized AI is revolutionizing smart factory automation, highlighting its transformative benefits and applications that are reshaping the manufacturing landscape. I find it fascinating how these advancements can significantly enhance operational efficiency while addressing critical challenges such as data security and system resilience. Key Points:

- Decentralized AI enhances resilience in smart factories by utilizing self-healing algorithms, allowing systems to autonomously adapt to disruptions, which is crucial for continuous operations.

- The integration of blockchain with decentralized AI fosters trust and transparency in manufacturing processes through secure data provenance and collaboration across nodes, ensuring compliance in complex supply chains.

- Federated learning models enable multiple factories to improve AI performance while maintaining data privacy, striking a balance between innovation and regulatory compliance.

Understanding the Impact of Decentralized AI on Smart Factories

How Smart Factory Automation Works with Advanced Technologies

Understanding Smart Factory Automation

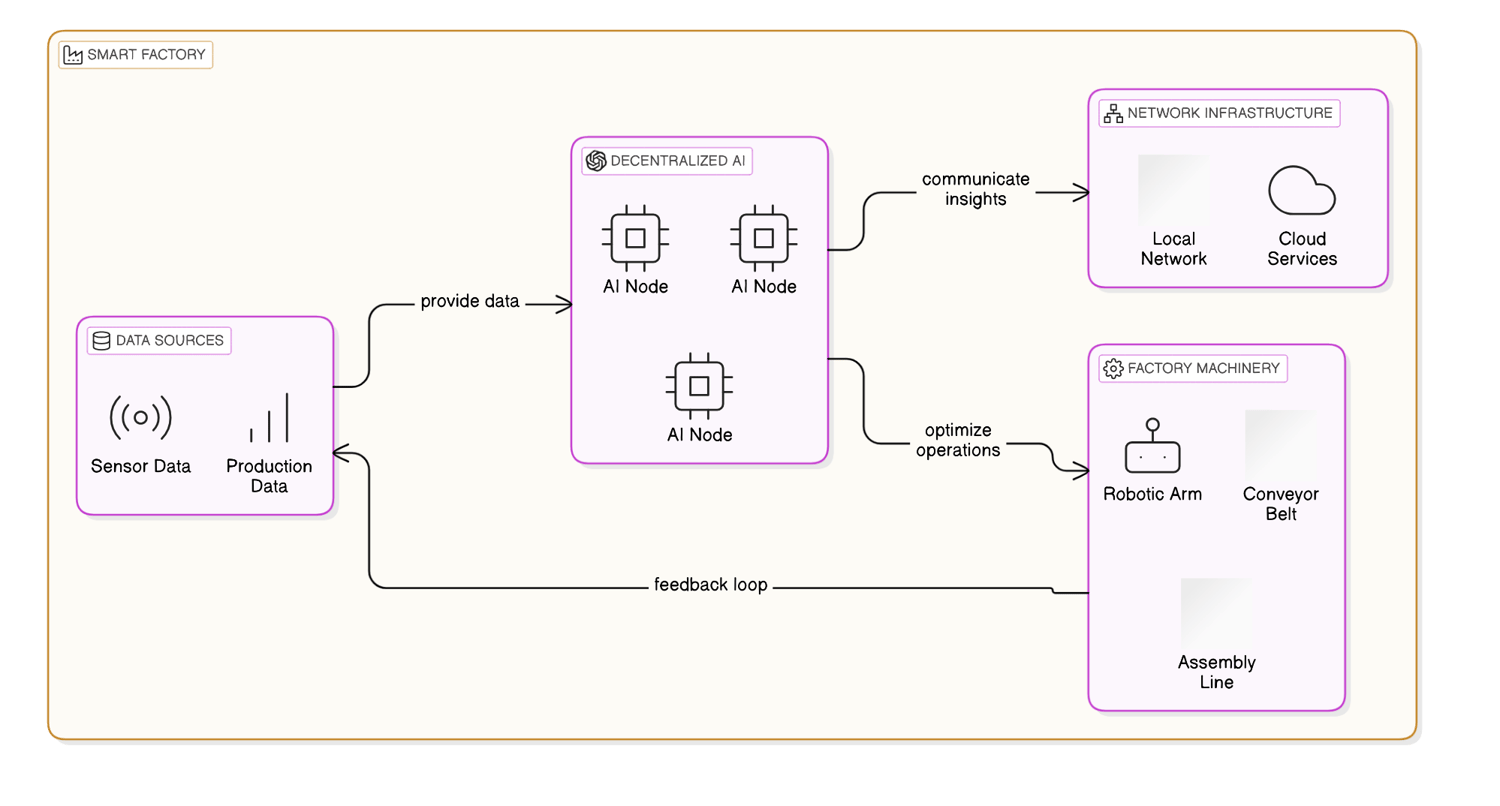

Smart factory automation is an intelligent and efficient production model achieved through the integration of cutting-edge technologies such as robotics, artificial intelligence (AI), and Internet of Things (IoT) devices. IoT devices play a crucial role by providing real-time monitoring and control of machines and processes, ensuring stable data flow and operational oversight.

Furthermore, AI enhances automation by enabling predictive maintenance to foresee potential equipment issues and assisting in informed decision-making to optimize processes. Advanced technologies like sensors, data analytics, and cloud computing allow smart factories to operate more efficiently. For example, IoT sensors enable real-time monitoring to improve production efficiency, while AI optimizes production processes through algorithms to enhance product quality.

Overall, these technologies work together to shape a more flexible and efficient manufacturing environment.

| Aspect | Traditional Automation | Decentralized AI Automation |

|---|---|---|

| Data Processing | Centralized data processing with limited real-time analysis | Real-time data processing across distributed nodes, enabling immediate insights |

| Flexibility | Rigid systems requiring manual reprogramming for changes | Adaptive systems that learn and evolve automatically based on new data inputs |

| Scalability | Scaling up requires significant infrastructure investment and downtime | Seamless scalability through cloud-based decentralized networks with minimal disruption |

| Decision Making | Rule-based decision-making driven by predefined parameters | Intelligent decision-making using machine learning algorithms to optimize processes dynamically |

| Collaboration | Limited collaboration between machines, often isolated systems | Enhanced collaboration between machines and devices via peer-to-peer networks, leading to improved efficiency |

Identifying Limitations of Centralized Automation in Manufacturing

Exploring the Core Principles of Decentralized AI

Decentralized artificial intelligence introduces transformative capabilities to smart factory automation by leveraging advanced technologies and distributed frameworks to address the constraints of centralized systems.

One of the core principles is federated learning, which enables collaborative training of AI models across multiple devices and nodes within smart factories without the need to centralize sensitive data. This approach emphasizes data privacy and security, allowing each node to autonomously optimize computational models based on real-time data. This not only enhances production efficiency but also accelerates response times.

As a result, in smart factory automation, decentralized AI not only strengthens the overall system’s resilience but also promotes optimal resource allocation.

Free Images

Free ImagesBenefits of Edge Computing and Blockchain in Smart Factories

Advantages of Decentralized AI Over Centralized Systems

Blockchain Integration:

Blockchain guarantees trust and transparency between network systems by providing a secure and immutable record, which is essential for production data management. In smart factories, it can be used to ensure device connectivity, monitor supply sources, and verify production records. This integration not only enhances data integrity but also promotes decentralized decision-making within the manufacturing ecosystem.

Advantages Over Centralized Systems:

Faster Decision-Making and Reduced Latency: Decentralized AI processes data locally across multiple nodes, enabling near real-time decision-making.

Reduced Risk of Single Points of Failure: The distributed architecture minimizes the risks associated with system outages, enhancing data privacy and security.

Self-Optimization: Each node can autonomously adjust and optimize based on its specific environment, leading to greater efficiency and flexibility.

In smart factories, these features not only boost productivity but also strengthen a company's ability to respond quickly and adapt to market changes, ultimately enhancing its competitive edge.

Key Applications of Decentralized AI in Manufacturing Processes

Recognizing the Benefits Offered by Decentralized AI Solutions

Addressing Challenges in Implementing Decentralized AI Frameworks

Real-Time Quality Control Systems:

Leveraging decentralized processing capabilities, real-time quality control systems enable immediate defect detection and process optimization. Edge AI technology, applied within cameras or sensors, can inspect products on production lines in real time, identify anomalies, and provide instant feedback for corrective actions. This localized approach ensures high-quality output without the latency issues commonly associated with centralized systems.

Efficient Resource Management:

Decentralized AI effectively manages resources by dynamically adjusting energy consumption, raw material usage, and machine scheduling through local data processing.

Data Privacy and Security:

Considering the critical importance of data privacy and security, encryption technologies such as homomorphic encryption and blockchain are essential to safeguard data during sharing processes.

Interoperability Across Devices and Platforms:

Standardized protocols like OPC UA or MQTT are necessary to facilitate smooth information flow between various devices and platforms.

Governance Mechanisms:

In multi-stakeholder environments, clear and well-defined governance mechanisms are vital to avoid operational inefficiencies caused by ambiguous responsibilities.

Therefore, a flexible and adaptive system architecture is a key factor for the successful implementation of decentralized AI in smart factories.

The Future Potential of Decentralized AI in Transforming Industry Standards

Advantages of Decentralized AI in Smart Factories

Operational EfficiencyDecentralized AI promotes faster decision-making through local data processing, enhancing operational efficiency. Utilizing edge computing and real-time analytics, production lines can quickly respond to changes, reduce latency, and streamline processes. Additionally, AI-driven insights help minimize resource waste, ensuring effective use of labor, materials, and energy.

High ScalabilityUnlike centralized systems that struggle to scale workloads, decentralized AI supports seamless expansion. By distributing processing capabilities across various nodes, factories can efficiently handle increasing production demands without compromising performance. Therefore, decentralized AI is ideal for large-scale and rapidly growing manufacturing environments.

Data SecurityA decentralized architecture enhances data security by keeping sensitive information stored locally while utilizing blockchain technology for tamper-proof records. This approach mitigates risks associated with unauthorized access or breaches and ensures compliance with industry standards like GDPR and ISO. Furthermore, it reduces single points of failure and other risks linked to centralized data storage.

Cost ReductionBy optimizing processes and minimizing inefficiencies, decentralized AI contributes to significant cost savings. For example, predictive maintenance reduces expenses from equipment failures, while dynamic resource allocation helps cut energy and material costs. Over time, these improvements translate into lower operating expenses and increased profitability.

Challenges and Solutions

When introducing decentralized AI to smart factories, several obstacles must be overcome, such as building the necessary infrastructure and integrating advanced technologies with existing systems. To fully realize the potential of decentralized AI, these barriers must be addressed. DcentAI specializes in providing tailored solutions to ensure smooth adoption and maximize operational benefits:

Integration with Legacy SystemsTraditional factories often rely on legacy systems designed for centralized workflows, making the integration of decentralized AI solutions challenging. These outdated infrastructures can create bottlenecks, hindering information exchange between new AI tools and existing equipment. DcentAI offers flexible APIs, middleware, and customized integration frameworks to bridge the gap between legacy systems and decentralized AI platforms. This approach enables gradual upgrades without overhauling the entire infrastructure. Additionally, their team provides expert consulting to help manufacturers develop phased integration plans, minimizing disruptions and ensuring compatibility with current workflows.

Data Synchronization IssuesMaintaining consistency across distributed nodes in a decentralized network is crucial, as data discrepancies or synchronization delays can lead to errors, inefficiencies, or security risks. DcentAI employs federated learning to coordinate AI models across multiple real-time nodes and utilizes blockchain technology for secure data recording. This ensures that each component of the manufacturing network has the most up-to-date and accurate information. Moreover, advanced algorithms for conflict resolution guarantee reliability and self-healing capabilities, even during temporary failures or disconnections.

Infrastructure RequirementsImplementing a decentralized system requires robust infrastructure, including edge computing devices, reliable connectivity, and scalable architectures to support distributed processing. Some factories may lack the human resources or technical expertise to build such infrastructure. DcentAI provides a scalable, modular architecture tailored for smart factories, designed to leverage edge computing solutions for real-time data processing at the source. This reduces reliance on centralized systems. Additionally, DcentAI collaborates with hardware vendors to offer pre-configured edge devices optimized for decentralized AI workloads, allowing manufacturers to gradually upgrade their infrastructure based on their needs. DcentAI also offers end-to-end technical support, from installation to maintenance, ensuring a smooth user experience.

Adoption ChallengesA lack of understanding and trust is a major barrier to adopting decentralized AI. Concerns about implementation complexity, costs, and ROI often delay adoption. DcentAI addresses these concerns through comprehensive industry-specific training programs, including interactive workshops, on-site demonstrations, and case studies showcasing successful implementations. Moreover, DcentAI collaborates with industry leaders to promote pilot projects, enabling factories to test decentralized AI technologies in controlled environments before full-scale deployment. This hands-on approach not only educates stakeholders but also builds confidence in the technology's value.

Conclusion

In the field of smart manufacturing, the shift towards decentralized management models is gaining momentum. This transformation not only enhances security but also improves scalability and efficiency. Despite facing key challenges such as latency, data synchronization, and legacy system interoperability, DcentAI continues to break traditional barriers with cutting-edge modular architectures and real-time coordination capabilities. We believe that decentralized management models will soon drive the global smart manufacturing ecosystem, offering flexible responses to rapidly changing market demands and achieving new heights of success.

Reference Source

Real-Time AI Applications: Implementing Decentralized AI ...

By decentralizing AI computing across edge devices, industrial automation systems offer low-latency decision-making, scalability, and ...

Source: Medium · DcentAIAI in Manufacturing: Use Cases, Benefits, & Examples

Robots and AI in automation systems can work alongside humans, increasing productivity and reducing human error, allowing companies to scale ...

Source: SparxITExploring Decentralized AI: The Intersection of Blockchain and ...

Decentralized AI seeks to distribute the power of AI across a more transparent, secure, and equitable framework, leveraging the synergy between blockchain and ...

Source: blaize.techAI in Manufacturing: Use Cases and Examples

AI for manufacturing is also revolutionizing warehouse management, enhancing efficiency with advanced automation and intelligent data insights.

Source: AppinventivAI and Web3: Revolutionizing Decentralized Technology

Key benefits include improved risk management by predicting market volatility and automated trading strategies that adapt to changing market conditions. In the ...

Source: Rapid InnovationDECENTRALIZED AI: TRANSFORMING ENTERPRISE ...

By leveraging technologies such as blockchain, decentralized AI enables data processing, decision-making, and model training to occur across ...

Source: LinkedIn · LiveplexAre Decentralized AI Models the Future of Secure and ...

Decentralized AI provides solutions without relying on central authorities, ensuring data privacy and reducing risks associated with centralized ...

Source: WritecreamArtificial Intelligence and Blockchain: The Definitive Guide

Key Benefits :Decentralized models enable users to train AI locally, ensuring the protection of sensitive data, while blockchain facilitates ...

Source: SmartDev

ALL

ALL Smart Ecosystem

Smart Ecosystem

Related Discussions