Summary

This article delves into the intricacies of selecting the right high-speed stepper motor for your project. It highlights essential considerations that can significantly impact performance and reliability, making it a valuable resource for engineers and designers alike. Key Points:

- Understand the importance of advanced thermal modeling and FEA simulations for high-speed stepper motor selection, which provides insights beyond traditional torque-speed curves.

- Explore how AI and ML can streamline the motor selection process by analyzing complex datasets for optimal configurations, significantly reducing design iterations.

- Learn about recent advancements in magnet materials and winding techniques that enhance power density and efficiency, crucial for high-speed applications.

What Makes a High Speed Stepper Motor Essential for Your Project?

A Startup’s Struggle: Why We Chose the Wrong High Speed Stepper Motor

| Key Considerations | Description |

|---|---|

| Torque-Speed Curve | Analyze the torque-speed curve for consistent output across speeds to ensure reliability. |

| Motor Design | Consider hybrid designs with permanent magnets and toothed rotors for enhanced precision. |

| Material Selection | Use neodymium magnets and laminated steel cores to minimize energy loss and heat buildup. |

| Step Angle Accuracy | Choose motors with smaller step angles (e.g., 1.8° or 0.9°) for smoother motion in high-precision applications. |

| Thermal Management | Evaluate cooling features and high-temperature-resistant materials for operation at high speeds. |

| Driver Compatibility | Ensure compatibility between motor, driver, and controller to maximize performance capabilities. |

The Turning Point: How We Identified the Right High Speed Stepper Motor

Mark leaned over her shoulder, frowning. “Are we missing something? The specs looked solid.”

“Maybe the specs don’t tell the whole story,” Sarah replied, pulling up a chart. “Look at this. The torque drops off after 700 RPM. It’s not handling the load like we thought it would.”

The room went quiet. Someone tapped their pen nervously, and another team member started scrolling through motor datasheets. “We need a better option,” Mark said finally. “Even if it costs more. We can’t afford another delay.”

After hours of research, Sarah found a motor with a 3.5 Nm torque rating and an integrated cooling system. “This one’s designed for continuous high-speed operation,” she said. “It’s $1,500, but it should work.”

Testing began immediately. This time, the motor stayed cool, even at 1200 RPM. Sarah sighed in relief. “Finally. This is what we needed.”

The tension in the room eased, but the lesson stuck. Specs on paper don’t always tell the full story.

Our Approach: Helping You Select the Perfect High Speed Stepper Motor

One team member suggested tweaking the load distribution. “Maybe we’re pushing it too hard in one direction,” they proposed. Another disagreed. “The issue might be the ambient temperature in the lab,” they argued.

Sarah sighed, leaning back. “We’re closer, but we’re not there yet.” The team decided to run another round of tests, this time monitoring environmental factors more closely. “Let’s see if we can find the missing piece,” Mark said, though no one was entirely confident.

Free Images

Free ImagesFAQ: What Should You Know Before Buying a High Speed Stepper Motor?

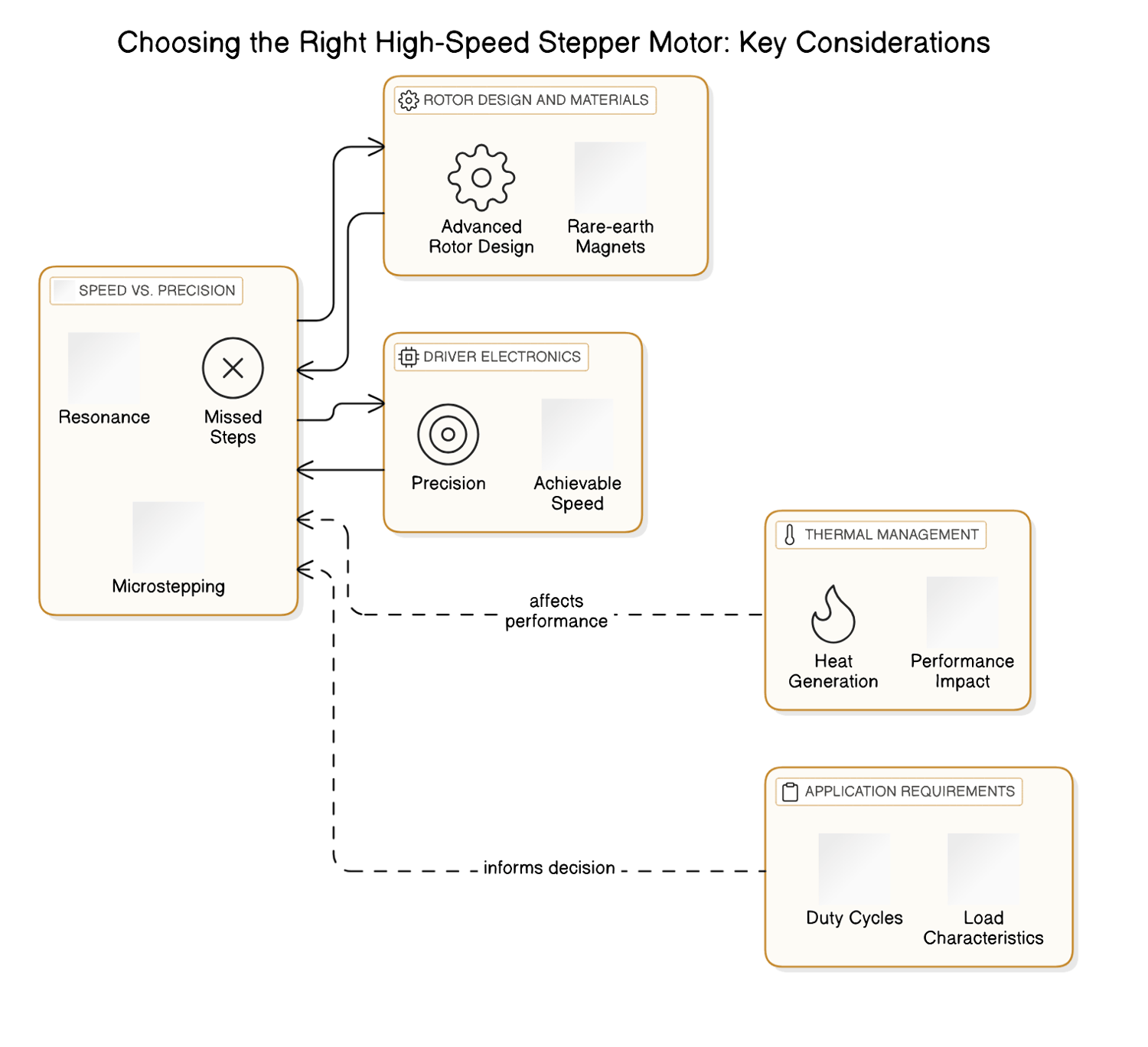

Another aspect that often gets brushed aside is the materials used in the rotor and stator. For instance, opting for laminated silicon steel can really help reduce eddy currents, boosting efficiency. It’s amazing how such material choices can impact performance!

You should also keep an eye on torque ratings at various speeds. High-speed operations might seem appealing at first glance, but they can actually lead to reduced torque due to back EMF—a detail that could cost you in performance if not considered.

Don't forget about compatibility with your driver circuit! Ensuring they work well together is key for achieving optimal performance. And let’s talk about thermal management; high speeds generate heat, so checking cooling requirements ahead of time can save you from potential overheating issues down the line.

Lastly, reflect on your project's specific needs regarding size, weight, and environmental conditions. Choosing a motor that checks all these boxes will make all the difference in ensuring its efficiency and reliability throughout your project journey! 🚀

Is Higher Speed Always Better? Debunking Myths About High Speed Stepper Motors

Balancing Speed and Precision: The Trade-offs in High Speed Stepper Motors

Step-by-Step Guide: How to Test and Choose a High Speed Stepper Motor

When embarking on a project that requires precision and speed, selecting the right high-speed stepper motor can make all the difference. This guide walks you through essential steps to test and choose the perfect motor for your needs, ensuring optimal performance and efficiency.

Having worked on several automation projects myself, I’ve encountered various challenges with stepper motors—some of which could have been avoided had I followed a more structured approach. Many people overlook critical factors like torque-speed curves and thermal management, leading to subpar results. By following this guide, you'll be better equipped to select a motor that truly meets your project's demands.

#### Step-by-Step Guide:

1. **Assessing Torque-Speed Curve**

Start by analyzing the torque-speed curve of potential motors. This curve illustrates how well a motor maintains its torque at higher speeds. Look for models with a consistent torque output across a broad range of speeds—this will ensure reliability in your application.

2. **Understanding Motor Design**

Consider hybrid designs that incorporate permanent magnets and toothed rotors. These configurations typically provide enhanced precision and efficiency compared to traditional designs (I find they also tend to run quieter!).

3. **Material Selection**

Pay attention to the materials used in the motor's construction. Neodymium magnets are ideal due to their strength, while laminated steel cores help minimize energy loss and heat buildup during operation.

4. **Evaluating Step Angle Accuracy**

Check the step angle accuracy options available (such as 1.8° or 0.9°). A smaller step angle results in smoother motion; thus, it’s crucial for applications requiring high precision.

5. **Thermal Management Considerations**

Now is an important moment: ensure you evaluate thermal management features! Motors designed with efficient cooling systems or constructed from high-temperature-resistant materials (think Class F or H insulation) are vital when operating at high speeds over extended periods.

6. **Checking Compatibility with Driver and Controller**

Lastly, verify compatibility between your chosen motor and its driver/controller setup—improper pairing can severely limit performance capabilities! Consult documentation carefully before making any decisions here.

(As a personal tip, I always keep a checklist handy during this process—it helps me stay organized!)

#### Advanced Tips & Reminders

If you're looking to further enhance your system's capabilities, consider integrating feedback mechanisms like encoders that can improve position accuracy significantly—especially beneficial in complex applications requiring real-time adjustments.

Additionally, remember that if you encounter specific issues like overheating or inconsistent performance later on, revisiting these initial selection criteria may shed light on necessary adjustments or upgrades needed for sustained success in your projects.

By following these practical steps thoughtfully and thoroughly evaluating each aspect of the high-speed stepper motors available to you, you're setting yourself up for not just meeting but exceeding project expectations! Happy tinkering!

What’s Next? Emerging Trends in High Speed Stepper Motor Technology

Final Thoughts: Making the Best Choice for Your High Speed Stepper Motor

As we move forward into an era where precision and efficiency are paramount, staying informed about advancements in motor technology will be key. Are you prepared to embrace these changes? Start exploring your options today—dive into product reviews, consult with experts, and experiment with different configurations to find the perfect fit for your unique requirements. The journey doesn’t end here; it’s just beginning!

Reference Source

Choosing the Right Stepper Motor for Your DIY Project

Speed Requirements. Consider the speed at which your motor needs to operate. If your project requires high-speed movements, choose a motor with a higher RPM ...

Source: Sherry MotorThe ultimate guide to buy the perfect stepper motor

I will give you a trick list and real advice, which will help you understand the best stepper motor to buy, figure out which motor that old printer has, or how ...

Source: Medium · Sergio MartinezMotor Selection Guide

There are 4 categories of electric motors that are used in practical applications and are easily available for purchase.

Source: PhidgetsHow Fast Can A Stepper Motor Turn? A Comprehensive Guide

The stepper motors can theoretically spin at thousands of RPM. However, the practical maximum speeds are typically between 500-1500 RPM depending on the motor ...

Source: smoothmotor.comBest Practices to Optimize Motor Selection

Optimizing motor selection for motion control applications can have significant performance, cost, and maintenance benefits.

Source: Tech BriefsGuide To Stepper Motor Selection | PDF

Choosing the right stepper motor depends on factors like the application requirements, system complexity, motor specifications, and physical characteristics.

Source: Scribd

ALL

ALL Smart Ecosystem

Smart Ecosystem

Related Discussions