Summary

Smart Ecosystem Integration is transforming the field of optics equipment by leveraging cutting-edge technologies to optimize performance and enhance research capabilities. Key Points:

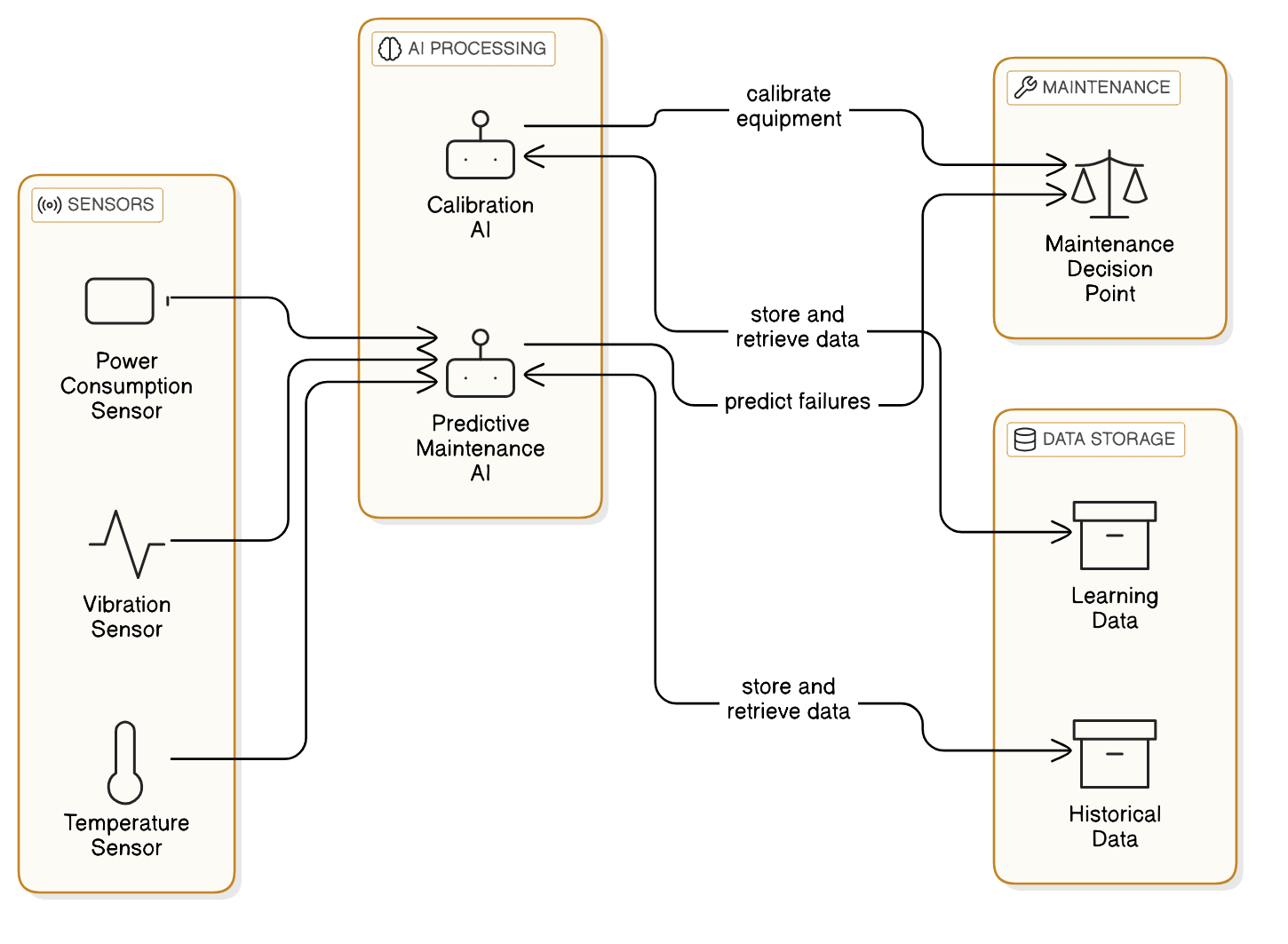

- AI-driven predictive maintenance enhances equipment reliability by anticipating failures, reducing downtime and costs.

- Quantum-enhanced sensing revolutionizes optics systems with improved precision and opens new avenues for scientific exploration.

- Robust cybersecurity measures protect sensitive data in interconnected smart optics networks, ensuring operational integrity.

Is Your Optics Equipment Underperforming? Unlocking Hidden Potential.

My First Optics Equipment Failure: A Story of Frustration and Lessons Learned.

Three hundred bucks down the drain just like that—it stung worse than a bee sting! We spent hours trying to fix what was obviously broken but ended up spinning our wheels in confusion instead of clarity. By evening, exhaustion weighed heavily on us; it dawned on me how much more there was to learn about optics than I had ever imagined. "I didn’t think it would be this hard," I admitted quietly, looking at Jake who just nodded slowly—none of us expected it would turn out like this.

| Integration Type | Key Features | Benefits | Latest Trends | Use Cases |

|---|---|---|---|---|

| Smart Optics Integration | Supports SDN and open controllers | Enhanced network management solutions | Growing emphasis on automation and AI in networking | Telecommunications, Data Centers |

| Optical Performance Optimization | Improves layer precision, reduces losses | Increased efficiency and reliability in optical systems | Focus on energy-efficient optics | Medical Imaging, Industrial Automation |

| Automation Technologies | Utilizes robotic arms and automated systems | Streamlined production processes with reduced manual intervention | Rise of Industry 4.0 principles in manufacturing | Manufacturing Lines, Quality Control Systems |

| Customizable Solutions | Tailored machines for specific industries | Flexibility to meet unique operational needs | Customization driven by customer feedback and market demands | Research Facilities, Specialized Manufacturing |

| Image Analysis & Measurement Systems | Advanced analysis for optical characteristics | Improved accuracy in optical performance assessments | Emergence of machine learning algorithms for data analysis | Quality Assurance Labs, R&D Departments |

The Turning Point: How I Finally Achieved Precision with My Optics Equipment.

Suddenly, it hit me how deep my confusion ran. The air grew thick; Jake was pacing back and forth, glancing at his watch like he was late for something important. “I thought you had it figured out,” he said softly, almost as if he were afraid of the answer.

Others began to murmur too—some flipped through manuals while others just stared blankly at the scattered parts on the table. We all felt something wasn’t right but couldn’t pinpoint what exactly—it was frustrating. A few moments later, an awkward silence settled in; even the sounds from outside faded away.

But then Dr. Emily’s calm demeanor cut through everything—the shift from chaos to clarity was palpable as she guided my hands on how to properly align those lenses without any breakage or issues that day.

Our Approach: Guiding You to Peak Optics Equipment Performance.

Dr. Emily observed from a distance, occasionally offering quick tips but mostly letting the group wrestle with their challenges. “It’s like we’re missing a piece of the puzzle,” Jake remarked, glancing at his watch as if time was running out on their experiment.

Some were optimistic about refining their methods, while others raised eyebrows at potential risks involved with further adjustments. The uncertainty hung thick in the air—“But what if this doesn’t work either?” someone whispered, leaving everyone questioning if clarity was truly within reach or just another elusive goal to chase.

Free Images

Free ImagesTroubleshooting Optics Equipment: Frequently Asked Questions (FAQ).

Another frequent concern is about misalignment – a small shift in the positioning of lenses can lead to significant distortion in your visuals. Regular calibration might sound tedious, but it’s essential for maintaining accuracy! I remember when I first started working with optical systems; a simple misalignment turned my crisp images into blurry messes until I learned the value of proper setup.

You might also wonder how environmental conditions play a role. Fluctuating temperatures can affect refractive indices and introduce focus errors. So keep an eye on your workspace environment! A well-controlled temperature can make all the difference.

Lastly, don't underestimate maintenance—keeping lenses clean and scratch-free ensures optimal performance. Dust particles are often overlooked but can severely degrade image quality. 💡 Here’s a little tip: always use microfiber cloths for cleaning!

Understanding these elements not only helps you troubleshoot effectively but also enhances overall efficiency and precision in your optical work."

Beyond Precision: How Can We Optimize Optics Equipment Efficiency?

The Cost vs. Performance Dilemma: Balancing Budget and Precision in Optics Equipment.

Practical Steps to Improve Optics Equipment Performance: A Hands-on Guide.

When it comes to enhancing the performance of optics equipment, taking a systematic approach can make all the difference. I recommend these steps not just based on theory but from real experiences in the field where small adjustments led to significant improvements in image quality and overall efficiency.

Many enthusiasts might not realize that optimizing your optics setup can prevent common pitfalls, such as distortion or loss of clarity. I once faced a frustrating situation with misaligned lenses that affected my imaging results; after re-evaluating and applying some practical strategies, I saw remarkable changes.

Here’s a straightforward guide to boost your optics equipment performance:

**Step 1: Optimize Lens Materials**

Begin by assessing your lens materials. High-index glass is a fantastic choice as it minimizes aberrations while improving light transmission. You’ll need to source quality glass from reputable suppliers (look for those with certifications). Remember, investing here pays off—better materials lead to clearer images.

**Step 2: Apply Coatings Wisely**

Next up is coatings! Using anti-reflective (AR) coatings significantly reduces glare and enhances contrast. If you're dealing with reflective surfaces, consider mirror coatings too. Ensure you have access to appropriate application tools; this step is crucial for maximizing light efficiency.

**Step 3: Check Alignment of Optical Components**

Now comes one of the most critical tasks—precise alignment of all optical components. Even slight misalignments can cause degradation in image quality. Use an optical bench if available and take your time adjusting until everything lines up perfectly (I usually double-check my adjustments by focusing on a test target).

**Step 4: Control Environmental Factors**

Environmental conditions play an essential role in optics performance. Keep temperature stable and humidity levels controlled using dehumidifiers or climate control systems if necessary. This precaution helps protect sensitive materials from distortion over time.

**Step 5: Regular Maintenance Practices**

Regular maintenance cannot be overlooked! Clean lenses using soft microfiber cloths and suitable solvents designed for optics—this preserves clarity without scratching surfaces. I personally set reminders every few months for cleaning sessions; staying proactive prevents buildup that could hinder performance.

**Advanced Techniques & Additional Tips**

If you're looking to take things further, consider implementing adaptive optics technology which dynamically corrects wavefront errors in real-time—a game-changer for high-performance applications! Also, regularly review calibration settings per manufacturer recommendations; this ensures optimal functioning over time.

Should you wish to explore more advanced applications or troubleshoot specific issues down the road, joining forums or communities dedicated to optical engineering can provide valuable insights from fellow professionals who share their experiences and solutions.

By following these actionable steps with care and attention, you'll find yourself well-equipped to enhance both precision and efficiency within your optics setup—leading not only to better results but also greater satisfaction in your work!

The Future of Optics Equipment: What Innovations Should We Anticipate?

Conclusion: Maximize Your Optics Equipment Investment for Lasting Success.

Now is the time to take action—evaluate your current practices, seek ways to incorporate these strategies into your operations, and stay ahead of the curve in this dynamic field. The trend towards higher performance in optics equipment is here to stay; how will you adjust your methods to meet these new standards? By prioritizing innovation and efficiency today, you can ensure that your investment yields lasting success well into the future. Let's embrace the possibilities ahead!

Reference Source

Smartoptics | Connecting people around the globe

Smartoptics provides innovative open networking solutions and devices, solving network challenges and increasing the competitiveness of our customers.

Source: Smartoptics自動化智慧製造| BUENOOPTICS和全豐光電

智能光學檢測與自動化整合機器手臂應用、各類自動化系統整合等技術,提供產業界在自動光學檢測設備與產線自動化整合需求等相關實務應用案例,有效應用於工業自動化之 ...

Source: buenooptics.comOpen management solution for open line systems

The objective of Smartoptics is to develop an orchestrator supporting SDN and open controllers. The management solution will initially focus on all existing ...

Source: SmartopticsSmart Optics

We work on smart optics by optimizing layer precision, minimizing losses, increasing homogeneity over a larger area, and by improving power compatibility.

Source: Laser Zentrum HannoverSmartoptics – Independent Data and Networking Solutions

Smartoptics provides innovative and scalable optical networking solutions and devices for the new era of open networking.

Source: Independent Data SolutionsAutomatic optical measurement/inspection equipment solutions

We can customize semi-automatic machines, automated machines, mass production lines, robotic arm applications, special fixtures, smart sensor ...

Source: 展昭展覽網Microscope Automation | Optical Instrumentation - Total Smart ...

Expert in image analysis, image measurement and optical characteristic measurement system integration. Provide professional Image analysis , Image ...

Source: 中惠科技Shuz Tung Machinery Industrial Co., Ltd.

Shuz Tung is a high-quality Semiconductor Automation Equipment, Semiconductor Metrology and Inspection Equipment, Flat Panel Display Turn-key Equipment, ...

Source: wisepioneer.com.tw

ALL

ALL Smart Ecosystem

Smart Ecosystem

Related Discussions