Summary

This article delves into the essential components you need to ensure your 3D printer operates at its best, highlighting the latest advancements in technology and materials. It provides valuable insights that can enhance your printing experience, whether you`re a hobbyist or a professional. Key Points:

- Explore advanced materials like high-performance polymers and metal alloys for enhanced durability and precision in 3D printing.

- Discover AI-driven predictive maintenance techniques that optimize printer performance and prevent failures in real-time.

- Learn about the benefits of modular designs, allowing for customizable printer setups and greater innovation through open-source contributions.

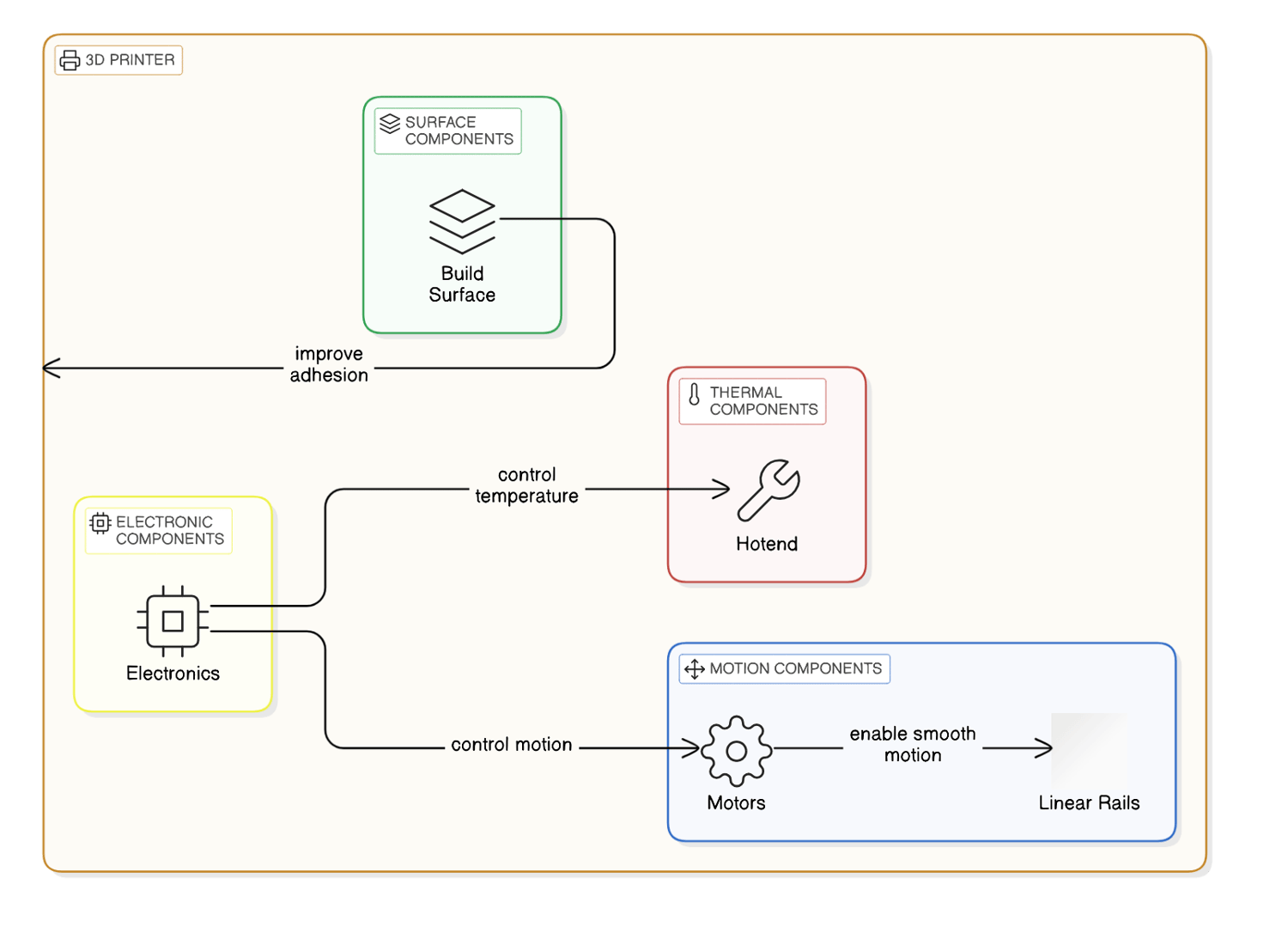

Why Are the Right 3D Printer Parts Crucial for Your Success?

A Beginner’s Struggle: How Missing Parts Led to Print Failures

| Part Name | Function | Material Compatibility | Impact on Print Quality | Maintenance Frequency | |

|---|---|---|---|---|---|

| Hotend | Melts filament to create layers | PLA, ABS, PETG, TPU | Essential for consistent extrusion and layer adhesion | Regular cleaning recommended after every 10 prints | |

| Build Plate | Surface where the print adheres during printing | Glass, PEI, Metal, Magnetic surfaces | Affects first layer adhesion and overall print success rate | Inspect for warping or damage before each print | |

| Nozzle | Controls filament flow during printing process | .2mm to .8mm sizes available for different detail levels | Compatible with most thermoplastics | Directly influences resolution and detail quality | Replace when clogged or worn out (variable usage) |

| Cooling Fan(s) | Cools down printed layers to prevent warping | N/A (works with all filaments) | Crucial for maintaining dimensional accuracy in overhangs and bridges | Check functionality regularly; replace if noisy or ineffective | |

| Filament Spool Holder | Supports filament spools ensuring smooth feeding of materials | N/A (supports various spool types) | Indirect impact by preventing tangles that can cause jams during printing. | Minimal maintenance; check alignment occasionally |

The Turning Point: Discovering the Importance of Quality Components

How We Helped Transform Their 3D Printing Experience

Free Images

Free ImagesFrequently Asked Questions About 3D Printer Parts

Another common query is about the hotend and its PTFE liner. You might not realize that this little detail can make a huge difference in how smoothly the filament flows during printing. If you're experiencing clogs, it could very well be due to wear and tear on this part! 🔧

And let's talk about build plates—did you know that using glass versus PEI-coated aluminum can influence adhesion? I remember struggling with prints lifting off during production until I switched to a PEI surface; now, my prints stick perfectly!

Lastly, many enthusiasts ask why stepper motors matter so much. These small but mighty components drive precise movements essential for high-quality prints. Investing in high-quality stepper motors pays off in performance and longevity.

So next time you're troubleshooting your 3D printer, consider these vital parts! Regular maintenance and understanding their roles can really elevate your printing game! 💡

What Makes Some 3D Printer Parts More Durable Than Others?

Is It Worth Investing in Premium 3D Printer Parts?

Step-by-Step Guide to Selecting the Right Components

When it comes to assembling or upgrading your 3D printer, the choice of components can significantly impact your printing experience and outcomes. I’ve spent countless hours tweaking my setup, and trust me, selecting the right parts is crucial for achieving optimal performance and print quality. Many enthusiasts don’t realize that even small changes in component selection can lead to substantial differences in results.

#### Step-by-Step Guide to Selecting the Right Components

1. **Choose Your Extruder Wisely**

The extruder is pivotal since it directly affects how filament is fed into the hotend. If you plan on using high-temperature thermoplastics like nylon or PETG, opt for a metal extruder for durability. For common materials like PLA, a plastic extruder suffices (and it's lighter!). Remember, this decision sets the tone for all your future prints.

2. **Select the Appropriate Hotend**

Now we're at one of the most critical points: picking a hotend that aligns with your desired print resolution. A volcano-style hotend offers faster extrusion rates—great if you're working on larger models—but may sacrifice some detail. Conversely, standard hotends excel at capturing fine details but may slow down larger jobs (I often find myself balancing speed and precision).

3. **Decide on Build Plate Material**

The build plate influences adhesion and surface finish during printing. Glass plates provide a smooth finish but might require extra work to keep prints adhered without warping; PEI sheets are fantastic for adhesion but could be more expensive upfront (a little investment goes a long way!).

4. **Pick Reliable Stepper Motors**

When selecting stepper motors, consider their torque ratings carefully—NEMA 17 motors are typical for desktop printers due to their balance of power and efficiency. Ensure they match your printer's weight requirements; otherwise, you might encounter skipping steps or misalignment during prints.

5. **Invest in Quality Belts and Rods**

Precision in motion makes all the difference! Invest in high-quality belts and rods—they minimize wobble which leads to smoother movements during printing (a tip: I always double-check belt tension before starting new projects). Look out for backlash as well; it can ruin those perfect curves!

#### Advanced Tips

If you're keen on taking things up a notch after you've got everything set up perfectly, consider experimenting with different configurations based on specific materials or projects—a good practice is running test prints before embarking on full-scale projects. Additionally, if you're still exploring options post-setup adjustments or facing consistent issues with layer adhesion or print failures, checking online forums can provide tailored advice from experienced users who've faced similar challenges.

With these steps in mind and a bit of experimentation along the way, you'll be well-equipped to make informed decisions about your 3D printer components—and elevate both its performance and your overall satisfaction! Happy printing!

What’s Next in the Evolution of 3D Printer Parts?

Wrapping Up: Essential Tips for Optimal 3D Printer Performance

Reference Source

Essential tools for every 3D printing professional

Glue stick. Build plate adhesion is an important part of creating great 3D prints. · Pliers. Pliers have a variety of uses, from print core ...

Source: UltiMaker3D printer parts: Essential components and functions

Read our blog on 3D printer parts. From mainboards to extruders, discover how to repair and upgrade your 3D printer's performance.

Source: AzureFilmTop 6 Essential 3D Printer Accessories

The most common 3D printer accessories include filament dryers, vacuum containers, dry boxes, different sized 3D printer nozzles, hardened nozzles, 3D printer ...

Source: Raise3DDoes anybody 3d print there parts? Want advice on what ...

I've been running 3d printed skids, chassis braces, link risers, servo & winch mounts for quite awhile. Self printed and bought. All holding up very well.

Source: Reddit · r/rccrawlerTop 10 Essential 3D Printing Materials Explained

Nylon, or Polyamide, is a high-performance 3D printing material known for its remarkable strength, flexibility, and chemical resistance. It has excellent layer ...

Source: Objective3DMaintain a smooth operation with essential 3D printer parts

High-quality materials: Use high-quality filament or resin to avoid clogs and jams that can damage components and require replacement.

Source: Protomont Technologies

ALL

ALL Smart Ecosystem

Smart Ecosystem

Related Discussions