Summary

This article explores the critical challenges of integrating Operational Technology (OT) with Information Technology (IT) in the context of Industrial IoT. It offers valuable insights and solutions that can significantly enhance security and efficiency in industrial environments. Key Points:

- Implementing Zero Trust Architecture enhances security by requiring verification for every access request, thereby protecting against sophisticated cyber threats.

- Leveraging AI-driven anomaly detection allows for proactive maintenance and operational efficiency, identifying potential issues before they escalate.

- Utilizing digital twin technology provides unparalleled insights into operational performance, facilitating better decision-making in OT-IT integration.

Understanding the Challenges of OT-IT Integration

## **Overcoming the Challenges of OT-IT Integration in Industrial IoT**

### Introduction:

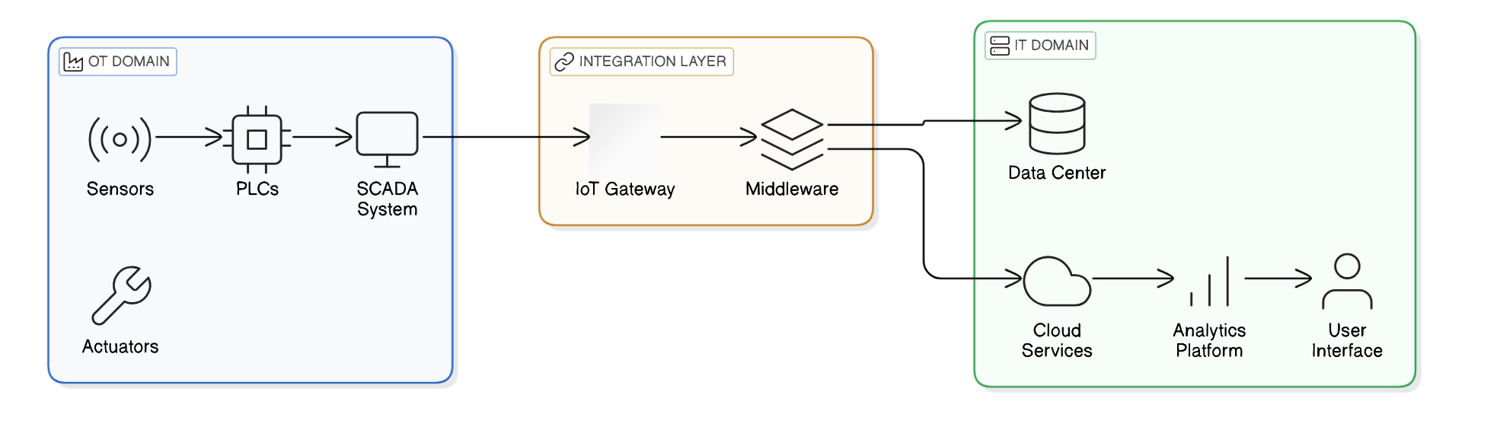

Embarking on the journey of integrating operational technology (OT) and information technology (IT) within the realm of Industrial Internet of Things (IIoT) presents a variety of hurdles. Organizations face an intricate landscape filled with outdated legacy systems and pressing demands for real-time processing. This blog will delve into these challenges more deeply, offering insights and practical strategies for overcoming them, supported by relevant examples.

The integration process is often complicated by the disparity between traditional manufacturing systems and modern IT frameworks. For instance, many facilities still rely on older machinery that doesn’t easily connect to newer digital platforms. To address this issue, companies can adopt structured methodologies such as the Purdue Model for enterprise architecture, which provides a clear framework for aligning operational processes with IT capabilities.

Another significant challenge lies in ensuring robust cybersecurity throughout the integration process. As organizations link their OT and IT environments, they expose themselves to potential cyber threats that could compromise sensitive data or disrupt operations. Implementing strong cybersecurity protocols is crucial; businesses must prioritize measures like regular security audits and employee training on best practices.

Data interoperability also plays a critical role in successful OT-IT integration. It’s essential that different systems are able to communicate effectively without compatibility issues hindering performance. Establishing data standards can facilitate smoother exchanges between various technologies, ensuring that all components work seamlessly together.

By examining real-world case studies where companies have successfully navigated these challenges, we can gain deeper insights into effective strategies for integration. Such examples not only illustrate practical applications but also make these challenges more relatable and actionable for organizations aiming to harness the full potential of IIoT through improved OT-IT alignment.

Identifying Key Personas for Effective OT-IT Integration

**Target Personas:**

1. **C-Level Executives (CEO, COO, CTO, CIO):**

**Why It Matters:** Discover how the integration of Operational Technology (OT) and Information Technology (IT) can fuel business growth, enhance operational efficiency, and create a competitive edge in today’s market.

2. **Operations and Plant Managers:**

**Why It Matters:** Learn effective strategies for boosting production efficiency and minimizing downtime through techniques like real-time monitoring and predictive maintenance.

3. **Quality Assurance Managers:**

**Why It Matters:** Gain insights into how unified quality management systems can improve product quality while ensuring compliance with industry standards.

4. **Maintenance Managers:**

**Why It Matters:** Explore innovative approaches to reduce unplanned downtime and streamline maintenance processes using predictive maintenance techniques.

By understanding these personas—recognizing their unique traits, responsibilities, decision-making powers, and communication styles—we can foster collaboration between OT and IT teams more effectively. Furthermore, emphasizing cross-functional training can help bridge any knowledge gaps that may exist. Tailoring strategies to each persona's distinct challenges will not only facilitate smoother integration but also promote a collaborative culture across departments.

| Challenge | Description | Solution | Example |

|---|---|---|---|

| Diverse and Legacy Systems Challenge | Integration of outdated machinery with modern IT frameworks. | Utilize middleware solutions and standardized communication protocols. | XYZ Manufacturing successfully unified legacy machines using middleware. |

| Real-Time Processing Requirements | OT environments require real-time data processing, conflicting with IT`s batch processing. | Implement edge computing for localized data processing. | ABC Manufacturing utilized edge computing to meet OT demands effectively. |

| Security Vulnerabilities | Risk of cyber threats increases when linking OT with IT systems. | Establish network segmentation, encryption, and regular security audits. | DEF Automotive bolstered security through network segmentation and continuous evaluations. |

| Data Quality Concerns | Inconsistent data formats can lead to inaccuracies in integrated systems. | Implement comprehensive data governance for standardization and validation checks. | GHI Foods enhanced decision-making by maintaining high-quality data through governance practices. |

| Organizational Silos | Independent operation of OT and IT departments hinders collaboration. | Foster cross-functional teams and promote regular communication between departments. | ABC Manufacturing improved integration efforts through joint training sessions and meetings. |

Addressing Diverse Legacy Systems in Industrial Environments

**6. IT Managers and Directors: Why It Matters:** Understand the nuances of overseeing and executing integration projects that connect operational technology (OT) with information technology (IT). Focus on key aspects such as system integration strategies and ensuring robust data security measures, which are critical for safeguarding sensitive information while facilitating seamless interactions between platforms.

**7. System Integrators and Solution Architects: Why It Matters:** Gain valuable insights into creating and implementing integrated systems that effectively bridge the gap between OT and IT realms. Leveraging middleware solutions alongside edge computing technologies can significantly streamline processes, making it easier to manage diverse systems while enhancing overall performance.

**8. Data Scientists and Analysts: Why It Matters:** Learn how to harness data from these interconnected systems to drive advanced analytics initiatives. This understanding paves the way for AI-driven insights that can lead to more informed decision-making across organizations, ultimately transforming raw data into actionable intelligence.

Meeting Real-Time Processing Needs with Edge Computing

**Diverse and Legacy Systems Challenge:** In many industrial settings, there exists a blend of legacy systems alongside modern equipment. These older systems often rely on proprietary protocols, which were not designed for seamless communication with contemporary IT solutions, creating hurdles in integration efforts.

At XYZ Manufacturing, the integration team, led by Ravi and Li Wei, encountered significant obstacles when trying to connect outdated machines with newer ones that operated on different protocols. However, through the clever use of middleware solutions combined with standardized communication protocols, they successfully established a unified platform that enabled all machinery to interact efficiently with one another.

Free Images

Free ImagesEnsuring Security in Integrated OT and IT Systems

**Real-Time Processing Requirements**

**Challenge:** Operational Technology (OT) environments often demand real-time processing with minimal delay to maintain safety and efficiency. However, integrating these needs with Information Technology (IT) systems, which typically favor batch processing and higher latency, presents a significant challenge. Li Wei observed that the existing IT infrastructure at ABC Manufacturing fell short in meeting the real-time processing demands of OT systems. To remedy this situation, they turned to edge computing solutions that facilitated local data processing right where it was generated. This approach not only cut down on latency but also ensured that OT requirements were satisfied promptly, allowing for swift responses to any emerging issues.

**Solution:** - **Edge Computing:** By implementing edge computing strategies, organizations can process data closer to its source, thereby minimizing delays and enabling real-time reactions. - **Hybrid Architecture:** A hybrid approach that integrates both edge and cloud computing can effectively balance immediate processing needs with long-term data management and analysis.

**Security Vulnerabilities**

**Challenge:** Historically, OT systems operated in isolation from external networks; however, incorporating Industrial Internet of Things (IIoT) technologies introduces new cybersecurity risks. Protecting OT environments from potential cyber threats becomes a pressing concern when integrating them with IT infrastructures. Afzal recognized this vulnerability while overseeing cybersecurity measures at DEF Automotive and took decisive action by establishing network segmentation along with encryption techniques and routine security evaluations to safeguard the integrated systems against attacks. These proactive steps helped ensure both the integrity of the factory's data as well as the continuity of operations.

**Solution:** - **Network Segmentation:** By segregating networks effectively, organizations can shield OT systems from direct interaction with IT environments—thereby reducing their exposure to potential cyber threats.

- **Zero Trust Architecture Principles:** Incorporating Zero Trust principles ensures continuous verification of users and devices while advocating for minimal access rights.

- **Advanced Encryption Technologies:** Utilizing robust encryption methods like AES-256 enhances data protection across all layers.

- **Hardware-Based Security Modules (HSMs):** Implementing HSMs offers an additional layer of security for sensitive information.

- **AI-Powered Real-Time Monitoring Solutions:** Employing AI-driven monitoring tools can facilitate anomaly detection in real time—enabling quicker threat responses while bolstering overall security in integrated OT-IT ecosystems.

Maintaining High Data Quality and Consistency Across Systems

A key challenge lies in ensuring high-quality and consistent data across various operational technology (OT) systems, which is vital for successful integration. Discrepancies in data formats and quality can result in inaccuracies and inefficiencies within the integrated system. To tackle this issue, it’s beneficial to establish comprehensive data governance frameworks that clarify data ownership, standardize formats, and employ advanced validation techniques to maintain accuracy. Moreover, integrating real-time analytics can facilitate ongoing monitoring of data integrity. Utilizing machine learning algorithms for detecting anomalies could also help identify inconsistencies early on. Finally, fostering collaboration between OT and IT teams is important for aligning goals and ensuring effective communication regarding data standards.

Bridging Organizational Silos Between OT and IT Departments

Planning for Scalability in Integration Solutions

A significant challenge faced by many organizations is the existence of silos between Operational Technology (OT) and Information Technology (IT) departments. These groups often have differing priorities, cultures, and processes that can hinder collaboration. Therefore, fostering a culture of cooperation between these divisions is vital for successful integration efforts.

Implementing Practical Solutions for Successful Integration

**Solution:**

- **Cross-Functional Teams:** It’s beneficial to establish cross-functional teams that can enhance cooperation between the OT and IT departments.

- **Regular Communication:** Encouraging ongoing communication along with joint training sessions can help keep stakeholders aligned on their goals.

Additionally, considering the use of standardized communication protocols such as MQTT or OPC UA could greatly facilitate seamless data exchange between OT and IT systems. Incorporating strong cybersecurity measures specifically designed for industrial environments—like firewalls and intrusion detection systems—is also crucial. Furthermore, adopting a modular architecture may provide added flexibility when scaling solutions. Lastly, utilizing real-time analytics tools will enable organizations to extract actionable insights from integrated data, thereby driving efficiency and informed decision-making across various operations.

Embracing the Future of Industrial IoT Through Seamless Integration

**Scalability Challenge:** One significant concern in this process is scalability. Integrating a handful of machines is quite different from integrating an entire facility or multiple facilities. Therefore, the solution must be both scalable and adaptable to support future growth.

The integration journey commenced with a pilot project at ABC Manufacturing, involving only a few machines. Following its success, the company proceeded to expand the integration throughout the entire plant, making sure that the solution remained flexible for upcoming demands. This gradual approach allowed them to fine-tune their strategy while guaranteeing scalability.

**Solution:**

- **Phased Implementation:** Initiate with a pilot project and progressively broaden the scope of integration.

- **Scalable Architecture:** Develop an integration architecture designed for scalability to facilitate future expansion.

- **Flexible Technologies:** Employ versatile technologies capable of adjusting to evolving requirements.

In summary, navigating the path toward OT-IT integration presents various challenges; however, these can be addressed effectively through appropriate strategies and solutions. By tackling issues such as diverse systems compatibility, real-time data processing capabilities, security measures, data quality concerns, organizational silos, and scaling needs, industries can achieve smooth integration processes. As shown by several companies' experiences, overcoming these hurdles results in improved operational efficiency, predictive maintenance capabilities, and enhanced decision-making processes. Embracing OT-IT integration has become crucial for businesses looking to succeed in today's rapidly evolving Industrial IoT landscape.

Reference Source

Navigating Industrial IoT: Key Challenges and Solutions

Explore the future of Industrial IoT with insights into challenges and opportunities, including cybersecurity, interoperability, ...

Source: IIoT WorldOvercoming the Top 10 Industrial IoT Challenges ...

Integration with Legacy Systems · Compatibility Issues: Older machines may lack the necessary interfaces or protocols to communicate with IoT devices seamlessly.

Source: Sustainable Manufacturing ExpoTips for Overcoming IT/OT Convergence Challenges

Overcoming challenges posed by fragmented data and inconsistent standards requires solutions that enable seamless data management at the edge.

Source: OctaiPipeUnderstanding and resolving the IT/OT gap

Industrial companies that report success with IT/OT integration efforts tend to stress the importance of listening and winning buy-in that extends across ...

Source: IoT World TodayWhy the Growing Adoption of IoT Demands Seamless ...

The integration of IT and OT through advanced IoT protocols represents a major step forward in securing industrial and healthcare systems.

Source: DataversityHow to Overcome the IT and OT Convergence Challenges ...

Successful deployment of IIoT requires collaboration between new-gen IT and traditional OT. Such integration poses a host of challenges.

Source: IT Knowledge ZoneMaximizing Industrial IoT Potential with OT-IT Integration

Why It Matters: Learn how OT-IT integration drives business growth, operational efficiency, and competitive advantage.

Source: Medium · Prashanth Y PIT/OT Convergence: Challenges and Opportunities in 2023

Business leaders need to build a holistic roadmap to integrate IT and OT systems. Learn how to overcome challenges and seize opportunities ...

Source: INCIT

ALL

ALL Smart Ecosystem

Smart Ecosystem

Related Discussions