Summary

In this article, we explore the pivotal role of Ball Screw Linear Actuators in boosting operational efficiency. From innovative materials to smart maintenance strategies, these advancements promise substantial benefits for various industries. Key Points:

- Utilizing advanced materials like titanium alloys and PVD coatings significantly enhances the efficiency and lifespan of ball screw linear actuators.

- AI-driven predictive maintenance enables real-time monitoring, forecasting potential failures, and optimizing maintenance schedules to minimize downtime.

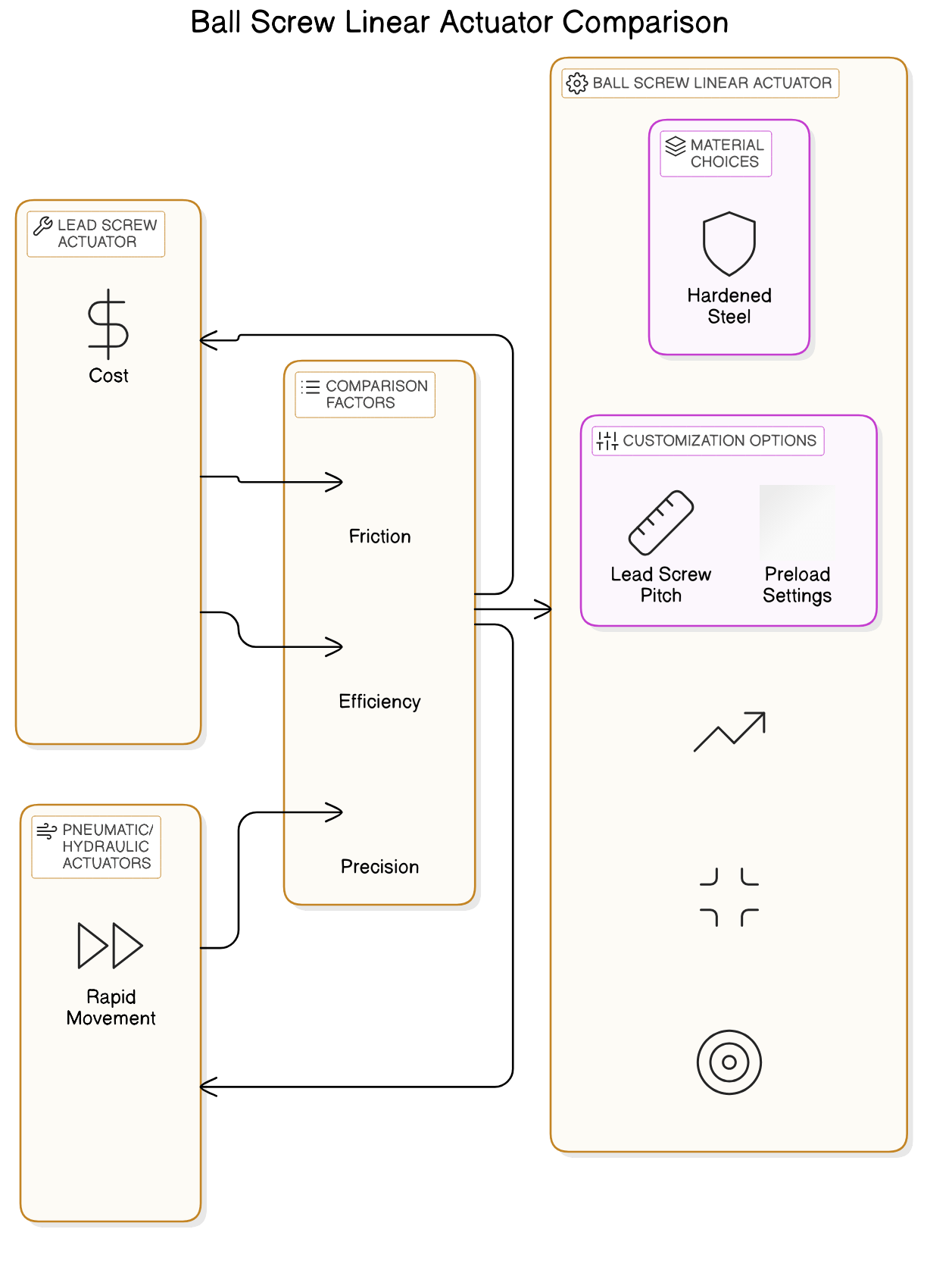

- The integration of hybrid actuation systems allows for versatile applications, combining the precision of ball screws with the power of hydraulic or pneumatic technologies.

What Makes Ball Screw Linear Actuators the Top Choice for Efficiency?

My First Ball Screw Linear Actuator Project: A Story of Trial and Error

After a quick test revealed a wiring blunder—one stupid mistake costing us an entire day—I could feel the weight of disappointment settling in. Each failed attempt seemed to chip away at my confidence; by week three, with deadlines breathing down my neck and parts strewn everywhere, I found myself wondering if this was really worth it. “This shouldn’t be this hard,” I sighed during another late-night session. My enthusiasm had turned into frustration—how had something so simple become such a massive headache? At that moment, we both just stared at each other in disbelief.

| Feature | Ball Screw Linear Actuator | Conventional Screw Actuator |

|---|---|---|

| Motion Type | Rotational to linear conversion | Rotational only |

| Friction Level | Minimal friction | Higher friction |

| Efficiency | Significantly higher efficiency with less torque required | Lower efficiency, higher torque needed |

| Duty Cycle Applications | Designed for high-duty cycle applications with precision and reliability | Suitable for low to moderate duty cycles |

| Size and Design | Compact designs ensure precise performance across various applications | Larger, bulkier designs may affect space utilization |

The Turning Point: Overcoming Challenges with Ball Screw Linear Actuators

“Maybe we should rethink our approach,” someone suggested hesitantly, but there was no enthusiasm behind it. Others just sat there with furrowed brows or stared blankly at their screens as if waiting for inspiration to strike.

It didn’t help that the deadline loomed closer—just five days left—and I could feel the tension creeping in like an unwelcome guest. “We’re running out of time,” I muttered under my breath, feeling the weight of responsibility pressing down on me.

A few moments later, I caught a glimpse of Mike biting his nails while flipping through pages of notes—clearly not finding any answers either. We all sensed something wasn’t right but couldn’t quite put our fingers on it. Then, silence fell over us again; it was almost deafening.

How We Help You Choose and Implement the Right Ball Screw Linear Actuator

With only days left on the clock, tension mounted. “What if we pivot to a different actuator type?” suggested someone tentatively. A few hesitated, weighing potential risks against deadlines. “It could work,” one optimist replied, but another retorted skeptically, “Or it could set us back even further.” As discussions spiraled into differing opinions and lingering doubts about their next steps lingered in the room, it became clear that clarity was still elusive.

Free Images

Free ImagesFrequently Asked Questions About Ball Screw Linear Actuators

Another common query is regarding customization options. You might be surprised to learn that parameters like lead, preload, and diameter can all be tailored to fit specific applications. This flexibility allows for an actuator that perfectly meets your system's needs—something many users don't realize until they start exploring their options!

And let’s not forget about maintenance! A lot of folks wonder how important lubrication is for these systems. The truth is, proper lubrication plays a crucial role in prolonging the lifespan of your actuator and maintaining its efficiency. So whether you're dealing with high-speed operations or harsh environmental conditions, ensuring you have the right type of lubricant can make a world of difference.

In summary, understanding these nuances can really help you choose the best ball screw linear actuator for your application! If you're still sorting through your options or want to dive deeper into any aspect mentioned here, feel free to ask more questions!

Beyond Efficiency: Exploring the Diverse Applications of Ball Screw Linear Actuators

The Ball Screw Linear Actuator vs. Alternatives: Weighing the Pros and Cons

Practical Guide: Selecting and Installing Your Ball Screw Linear Actuator

When it comes to enhancing the efficiency of your mechanical systems, selecting and installing a ball screw linear actuator can be a game changer. These devices effectively convert rotary motion into linear movement with minimal friction, making them an ideal choice for applications where precision is key. Having navigated this process myself, I can attest that following a structured approach not only streamlines installation but also boosts performance.

Many people overlook the importance of proper alignment during installation, which can lead to premature wear and tear. Trust me, I've encountered instances where neglecting this step resulted in costly repairs down the line. So let's dive into some practical steps that will guide you through the selection and installation process.

#### Step 1: Assess Your Requirements

Start by determining the specifications you need for your ball screw linear actuator. Consider factors like load capacity (how much weight it needs to handle), lead accuracy (the distance traveled per revolution), and environmental conditions (temperature ranges or contamination). This foundational understanding is crucial before moving forward.

**Tools Needed:** Data sheets for load calculations, measuring tools

**Tip:** Make a checklist of these parameters to ensure nothing gets overlooked!

#### Step 2: Choose Quality Materials

Select high-strength materials such as carbon steel or stainless steel for durability. The internal components like ball bearings should typically be made from hardened chrome steel to resist deformation over time.

**Important Note:** Investing in quality materials may seem like an upfront cost but will save you money in maintenance later on!

#### Step 3: Prepare for Installation

Before beginning the actual installation, gather all necessary tools—wrenches, mounting brackets, lubricants—and set up a clean work area where you can focus without distractions.

**Personal Habit:** I always set up my workspace with everything organized; it helps me keep track of what I have used and what’s still needed ⏱️.

#### Step 4: Align with Precision

This is one of the most critical steps! Use mounting brackets designed to maintain parallelism during installation. Misalignment at this stage can cause significant issues down the road.

**Reminder:** Double-check alignment using levels or laser guides before tightening any screws completely.

#### Step 5: Incorporate Lubrication Systems

To further enhance performance and longevity, consider integrating automatic lubrication systems if your application allows it. This minimizes friction over time and keeps everything running smoothly.

**Advanced Tip:** If you're feeling adventurous, look into smart lubrication technologies that adjust based on operating conditions!

### Advanced Techniques & Reminders

If you're interested in maximizing efficiency further or troubleshooting common problems post-installation—like unexpected noise or wear—consider consulting manufacturer guidelines on advanced tuning techniques specific to your model.

Also, don’t hesitate to reach out within community forums or consult professionals who have experience with similar setups; they often share invaluable insights that could save you time and headaches!

By following these steps diligently while keeping an eye out for potential pitfalls along the way, you'll not only streamline your project but also significantly enhance operational efficiency with your new ball screw linear actuator!

The Future of Ball Screw Linear Actuator Technology: What`s Next?

Conclusion: Optimizing Your System with the Right Ball Screw Linear Actuator

Moreover, as industries evolve and technological advancements continue to shape our landscape, staying ahead of these trends is crucial. The customization options available today—such as preload settings—offer opportunities for engineers to improve rigidity and minimize backlash further. This adaptability is essential in applications ranging from robotics to CNC machinery.

Now is the time to take action! Evaluate your current systems and consider how integrating an optimized ball screw linear actuator could propel your operations forward. Embrace this opportunity for innovation and improvement; after all, efficiency isn't just a goal—it's a continuous journey towards excellence in engineering.

Reference Source

Ball Screws | Ball Screw Linear Actuator - RS Components

A ball screw is a small mechanical linear actuator that translates rotational motion to linear motion with a small amount of friction. Ball screw assemblies ...

Source: RS 台灣Ball Screw Linear Actuator - TOYO Robotics

Toyo's electric actuator with ball screw mechanism is a linear motion device used in applications like positioning, pick and place, carrying, ...

Source: toyorobotics.coHow does a Ball Screw Linear Actuator work? | RENDER Support

The ball screw linear actuator is driven by the ball screw, guided by the linear guide rails, and equipped with a servo motor or a stepper motor.

Source: render.com.twDurable and Efficient Ball Screw Actuators

Ball Screw Actuators. Ball screw linear actuators are engineered for high-duty cycle applications, delivering exceptional precision, efficiency, ...

Source: Helix LinearBall screw linear actuators, steel, rolled or ground

Ball screw linear actuators are used for the precise positioning of workpiece carriers and for converting a rotary movement into a ...

Source: norelem USABall Screw | TBI MOTION TECHNOLOGY CO.,LTD

The high efficiency of ball screws is vastly superior to conventional screws. The torque required is less than 30%. Linear motion can ...

Source: TBI MOTION全球傳動Ball Screw Linear Actuators

Linear Actuator (External type)provides various types of combination for Ball Screw and Motor ranging from high precision to ...

Source: KSS Ball ScrewsBall Screw Linear Actuator 6mmx1mmx250mm NEMA 17 Motor ...

This compact ball screw linear actuator is part of our specialized series that provides precise and efficient performance. It ...

Source: PBC Linear

ALL

ALL Smart Ecosystem

Smart Ecosystem

Related Discussions